Clay Kit 2.0

The new WASP Clay kit 2.0 includes a 3 litre tank (which can be substituted with a 5 litre one, on specific demand).

The tank can be refilled or cleaned simply by opening the caps located at the each end. Inside, there is a piston with two 4 bar gaskets which pushes the material through the teflon pipe (diameter 12mm) which supplies the extruder. The cap located on the back has a safety valve set at 8 bar.

This technology allows the air to outflow upward , eliminating the probability of finding bubbles inside the mixture. Like for a common pressure extruder, if there were bubbles the flow would be interrupted and the print would be damaged.

Furthermore, thanks to the screw, the density of the printing materials is higher. This allows to reduce the time for their change of state, from liquid to solid, thus eliminating the risk of collapse of the printed object.

In case the screw or the chamber were damaged they can be easily substituted.

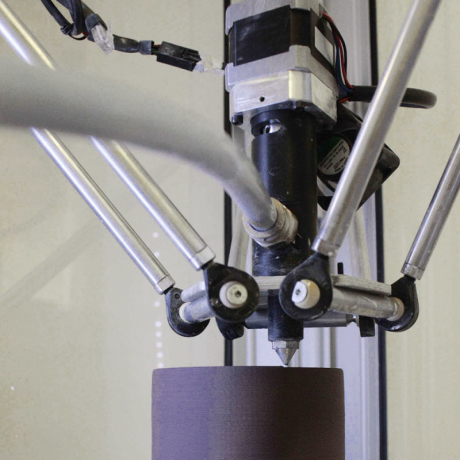

LDM (liquid deposit modelling) is the name of the new WASP clay kit for ceramic materials

Ceramic 3D Printer Examples